A major cold chain logistics company with a new-generation large-scale cold storage facility capable of handling tens of thousands of tons of goods daily sought to enhance storage efficiency, reduce labor costs, and ensure food safety. To achieve these goals, the company decided to adopt an advanced automated logistics solution. After extensive evaluation, they chose to partner with LSROBOT and implement its 3D SLAM unmanned forklift system.

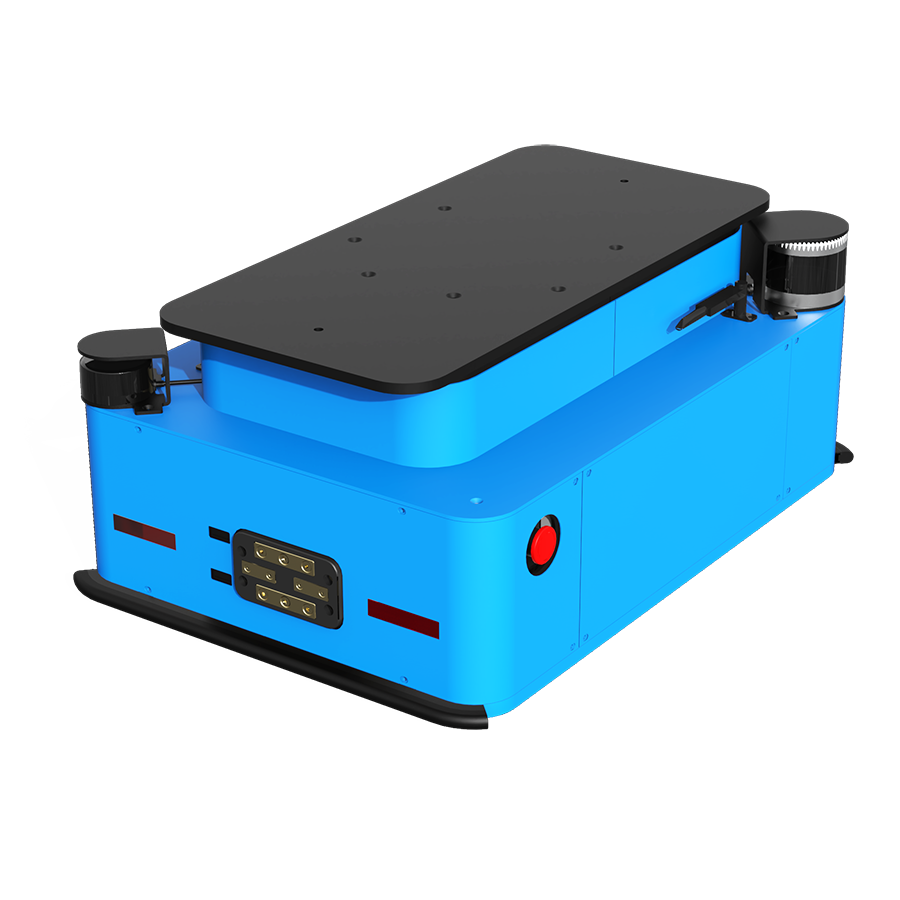

LSROBOT designed a tailored unmanned forklift solution for the company, utilizing the LXP15-B counterbalance-type forklift. This model, with a robust load capacity of up to 1.5 tons and excellent lifting capabilities, easily meets the demands of high-rack storage and retrieval. Considering the challenges of cold chain environments, such as significant temperature fluctuations and frost formation, LSROBOT equipped the forklifts with a special anti-condensation and defrosting technology. This effectively mitigates condensation issues, reduces battery consumption, and enhances navigation accuracy.

During the project implementation, LSROBOT’s team conducted a comprehensive evaluation of the cold storage environment before completing the deployment and fine-tuning of the unmanned forklifts. Using true 3D SLAM natural navigation and positioning technology, the unmanned forklifts operate stably in the dynamic and complex cold storage environment, achieving precise positioning and route planning. Additionally, the unmanned forklifts are equipped with an all-around 3D safety protection system to avoid collisions during material handling, ensuring operational safety.

“Since implementing LSROBOT’s unmanned forklift system, our cold chain logistics efficiency has significantly improved,” said the company’s logistics manager. “The forklifts have reduced manual operations, lowered labor intensity, and greatly increased storage density and cargo turnover rates. More importantly, the anti-condensation and defrosting technology ensures stable equipment performance in the cold chain environment, giving us greater confidence in food safety.”

Through this collaboration, the cold chain logistics company has not only achieved automated upgrades in its storage and logistics operations but also reduced operating costs and enhanced market competitiveness. In the future, the two companies plan to deepen their partnership, exploring additional application scenarios for unmanned forklifts in cold chain logistics and jointly advancing the intelligent development of the industry.